driven by the new crown, Taobao, Jingdong already have a lot of ultraviolet disinfection of various types of products.

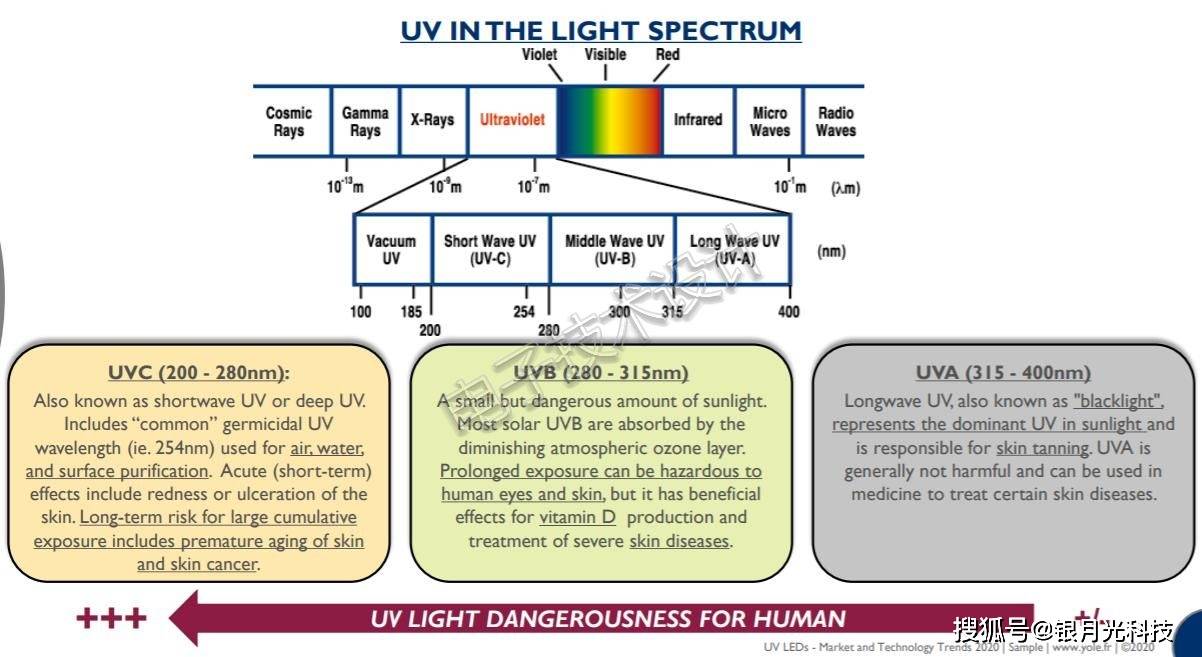

as shown in the figure below, the industry usually divides ultraviolet rays into three categories: A, B and C, namely near ultraviolet (UVA), far ultraviolet (UVB) and ultra-short ultraviolet/deep ultraviolet (UVC), of which UVC has the largest energy and is extremely destructive to microorganisms.

Compared with UVB and UVA,UVC is the first choice for healthy light sources. Compared with chemical sterilization, UVC has the advantage of high sterilization efficiency and no other chemical pollutants.

China has a complete UVC semiconductor industry chain, UVC semiconductor chip, packaging technology and material performance put forward higher requirements, chip technology is the main bottleneck and core competitiveness of deep UV semiconductor technology, industry-leading large factories and UV LED segments of the leading enterprises in the field of investment continues to increase.

outbreak has accelerated the development of the UVC semiconductor industry chain, with the UVC market growing from $20 million in 2008 to $0.1 billion in 2015, $0.144 billion in 2019, and directly doubling to $0.308 billion this year. According to the Yole Developpement report, the UVC market could reach $2.5 billion in 2025, driven by the coronavirus, with a compound annual growth rate of 61% from 2019-2025.

China, it is estimated that from 2020 to 2024, the market size of UVC sterilization modules in washing machines, refrigerators, household air conditioners and UVC small household appliances will rise from 0.174 billion yuan, 0.185 billion yuan, 0.194 billion yuan and 1.5 billion yuan to 8.538 billion yuan, 8.927 billion yuan and 9.736 billion yuan 3.5 billion yuan respectively. It is estimated that the market size of UVC sterilization modules in automobiles will reach 13.459 billion yuan by 2024.

if capacity can keep up with demand, the number could be even larger.

Compared with UVB, UVC is the first choice for sterilization and disinfection applications.

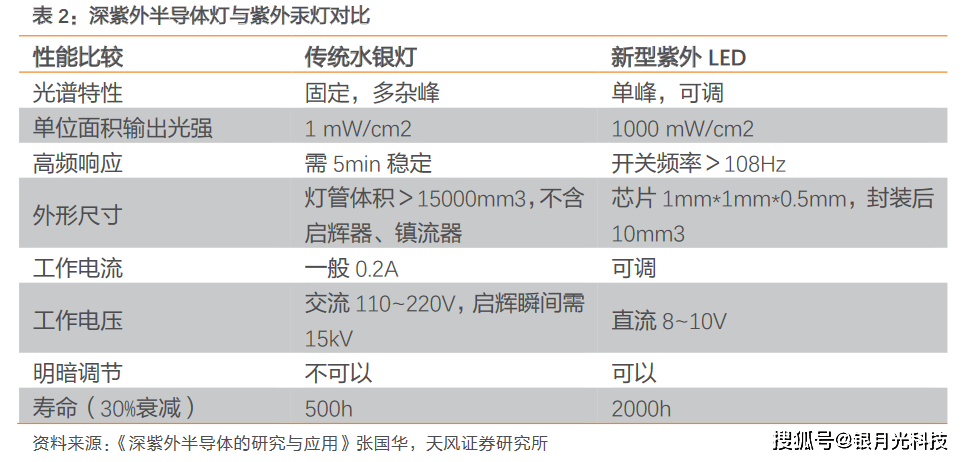

At present, there are two main ways to obtain UVC for sterilization and disinfection: traditional mercury lamp and ultraviolet LED. Compared with traditional mercury lamp, UVC semiconductor has obvious advantages: miniaturization, non-toxicity and convenient use.

In addition, UVC semiconductor process improvement direction is clear, technical problems continue to break through.

In this context, the traditional ultraviolet mercury lamp disinfection, sterilization products will be UV LED to accelerate the replacement.

According to the Yole report, the UV LED market is primarily driven by UV curing applications. However, a large number of Taiwan and mainland manufacturers have recently entered the UVA LED industry, resulting in strong price pressure, which limits the growth of the UVA LED market size.

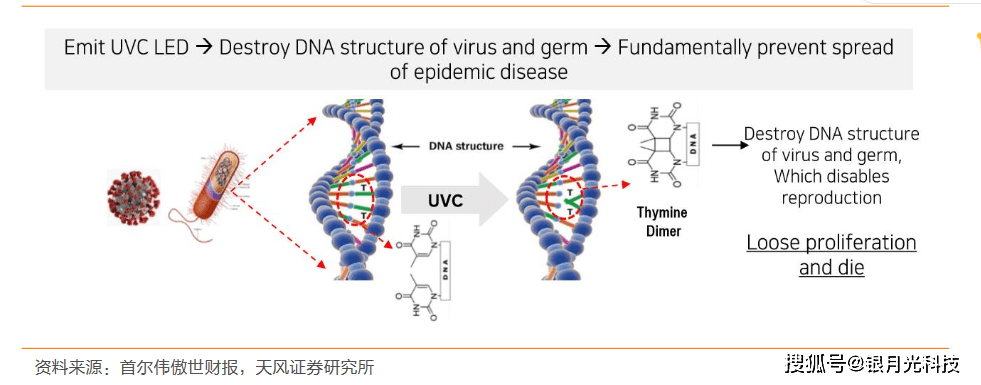

UVC sterilization principle

UVC sterilization principle

on the other hand, as equipment prices ($/mW) began to reach early demand, the UVC LED industry began to emerge. Pars Mukish, manager of Yole Dé veloppement's solid-state lighting and display business department, pointed out, "In fact, the price of UVC LED has reached 0.3-2 USD/mW from about US $100/mW in 2015 to 2019, which is a real threshold for most potential high-volume integrators."

2020 has acted as a catalyst, creating some perfect use cases for the technology to be promoted in a very short period of time.

and UVA compared with UVB, UVC penetration is not strong, will not cause harm to the human body, but the sterilization effect is almost the same, so UVC has become the first choice for sterilization and disinfection applications.

2020, there is an overall shortage across UVC's supply chain, and the industry is now looking for ways to rapidly add capacity.

deep ultraviolet semiconductor is roughly the same as that of the ordinary LED, but due to the different light-emitting materials UV-LED, the selected light-emitting materials and packaging forms will be different.

UVC semiconductor chip can be divided into two parts: a substrate and an epitaxial layer: the substrate usually follows the sapphire substrate used by the blue LED chip, and the epitaxial layer includes an AlN template layer, an N-type AIGaN layer, a multiple quantum well light-emitting layer, an electron blocking layer and a P-type GaN contact layer.

chip process, through photolithography, etching leakage of N-type contact layer, through evaporation and alloy, N-type, P-type and electrode ohmic contact, and then through thinning, splits, sorting of small core particles, flip-chip to the insulated silicon wafer.

After more than 10 years of research and development, the external quantum efficiency of deep ultraviolet semiconductors below 280nm has exceeded 5%, corresponding to a luminous power greater than 5mW and a lifetime of 5000h.return to Sohu, see more

Responsible Editor: